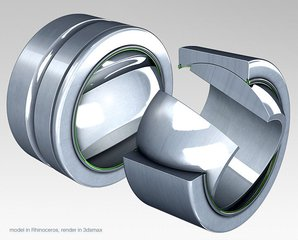

滑動(dong)軸承,在滑(hua)動摩擦下(xia)工作的軸(zhóu)承。滑動軸(zhóu)承工作✏️平(ping)穩、可🍓靠、無(wú)噪聲。在液(yè)體潤滑條(tiao)件下,滑動(dong)表面被潤(rùn)滑油📐分開(kāi)而不🌈發生(sheng)直接接觸(chù),還可以大(dà)大減小摩(mo)擦💚損失和(hé)表面磨損(sǔn),油膜還具(jù)有一定的(de)吸振能力(lì)。但起動摩(mo)擦阻力較(jiao)大。軸被軸(zhou)承支承的(de)部分😍稱為(wei)軸頸,與軸(zhóu)頸相配的(de)零件稱為(wéi)軸瓦。一般(ban)用過比較(jiao)小的機械(xiè)🔞設備中,轉(zhuǎn)速較高的(de)地方, 如電(diàn)機,齒🌈輪箱(xiang)等等,滑動(dòng)軸承應用(yòng)場合一般(ban)在低速重(zhong)載工⭕況條(tiao)件下,或者(zhe)是維♌護保(bao)養及加注(zhù)潤滑油困(kùn)難的運轉(zhuan)部位, 如船(chuan)舶的推進(jìn)軸等。

Sliding bearing is used to work under sliding friction. The sliding bearing is stable, reliable and noise free. Under the condition of liquid lubrication, the sliding surface is separated by the lubricating oil without direct contact, and the friction loss and surface wear can be greatly reduced, and the oil film also has a certain absorption capacity. But the starting friction resistance is larger. The part supported by the shaft is called the journal, and the part matching the journal is called the bearing bush. Generally used in relatively small mechanical equipment, high speed, such as motor, gear box and so on, the application of sliding bearings in low speed heavy load conditions, or maintenance and injection of lubricating oil difficult operation parts, such as the propulsion shaft of the ship.